Tees from the Land of the Rising Sun

A few seasons back I was very honoured to be one of four retailers in the country to trial a brand new premium t-shirt company by the name of Revolver set up by Colin Campbell. One rebrand later and now stocked by some of the best indies in the country you can see why I choose to purvey brands with a great back story and ethic.

Now available online or in-store, click here to view Sunray Sportwear.

With kind permission, an article published in Proper Mag is reproduced below.

Read on…

NS: Cornwall/Japan, how does that work?

CC: Although I’m not originally from Cornwall, I have lived here now for 30 years. My love of surf, the need to run away to drop out of society and start our own business led me and my wife Emma to venture West. Working with Japan is no harder than working with people in the UK or anywhere else in the world and, once you understand their culture and psyche, they are probably the easiest people I have ever worked with. They always look at ways of saying ‘yes’.

Why is literally everything from Japan so amazing?

The one thing I notice in everything they do, is ‘Excellence is Standard’ and I mean everything. They are unable to think there is another way. Culturally, their honour, their respect, gratitude, manners, their humble nature, the whole shebang is beautiful, and they apply that to everything. When you put all that together they literally cannot do anything that is even remotely substandard. Experiencing this first-hand has really driven me to sharpen everything I do such is the impact they have had on me.

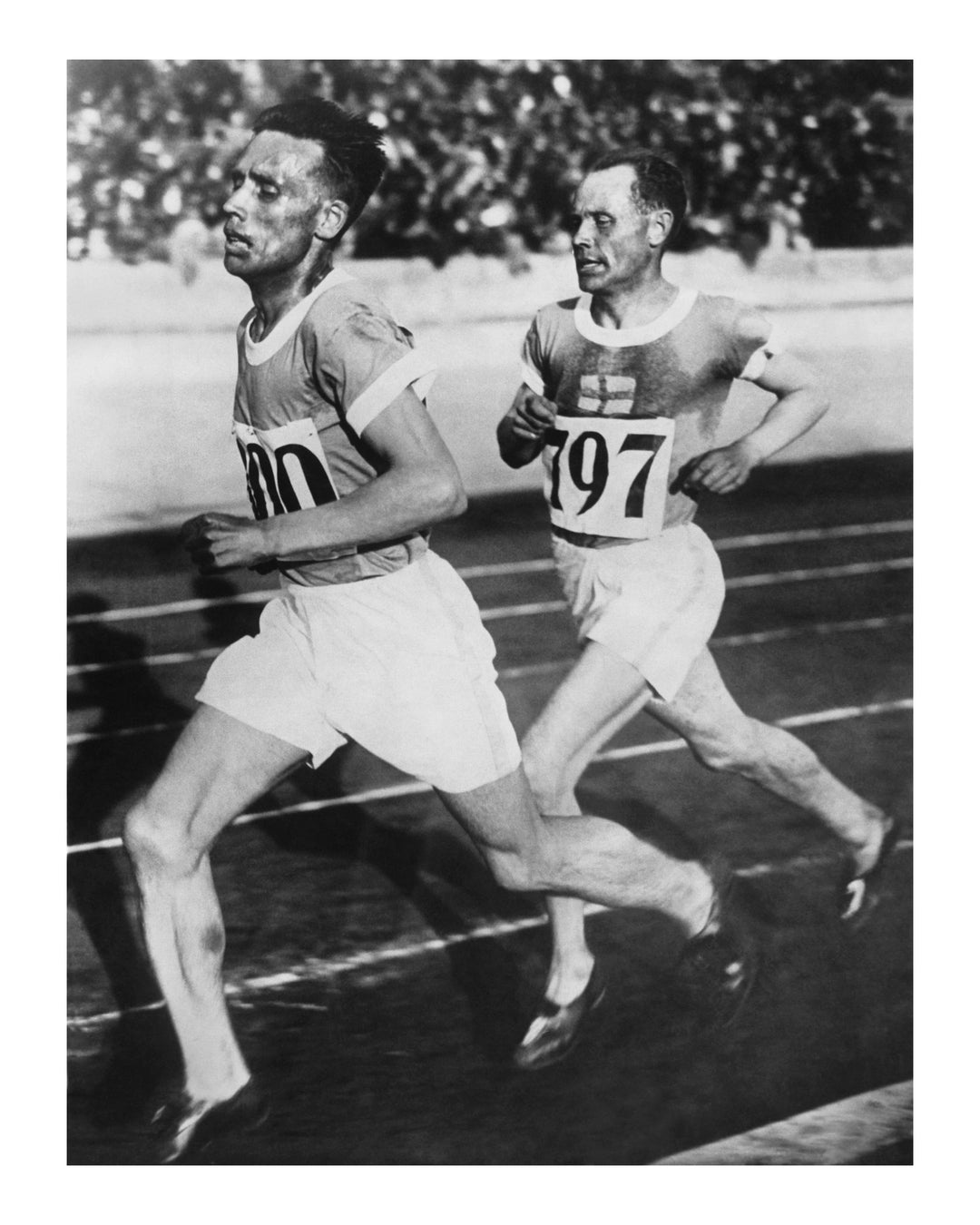

I hear there’s some seriously old school machinery involved?

When I set out to produce that high-quality T-shirt it quickly became clear that to get the very best it had to be made in Japan and on the old machines. Here is where I seriously lucked in. The wonderful guys who produce Sunray’s garments have been around for just under 100 years, once making uniforms for the Imperial Palace having been in the same family for generations and this history meant they also had access to these old machines. It took a few years of talking with them before I was allowed access to both producer and machines and I honestly feel blessed that they allow me to produce with them such is their esteem and provenance. One guy has worked there for over 62 years, another 32 years, one lady has been sewing for over 50 years. Can you imagine as a rookie brand having access to all that knowledge?

Add that experience to their desire for excellence and you can understand why I feel so lucky. All Sunray’s garments are made on antique knitting machines that knit tubes of fabric, hence there is no side seam. These machines were made redundant in the 50’s when the emphasis changed to volume at the expense of quality. These old machines work in a wonderfully archaic way that really does offer love to every inch of jersey they produce. The cotton yarn is laid down in one long circular motion at just 24 revolutions a minute, without any form of tension and dragging in air to sit between each layer. This process offers a jersey that no other can even get close to, it is that special.

It is so slow it can only produce 1m of fabric per hour. The average medium T-shirt takes about 1.2m. When you then add the very slow nature of putting the T-shirt all together, every Sunray garment takes over 1.5 hours to make.

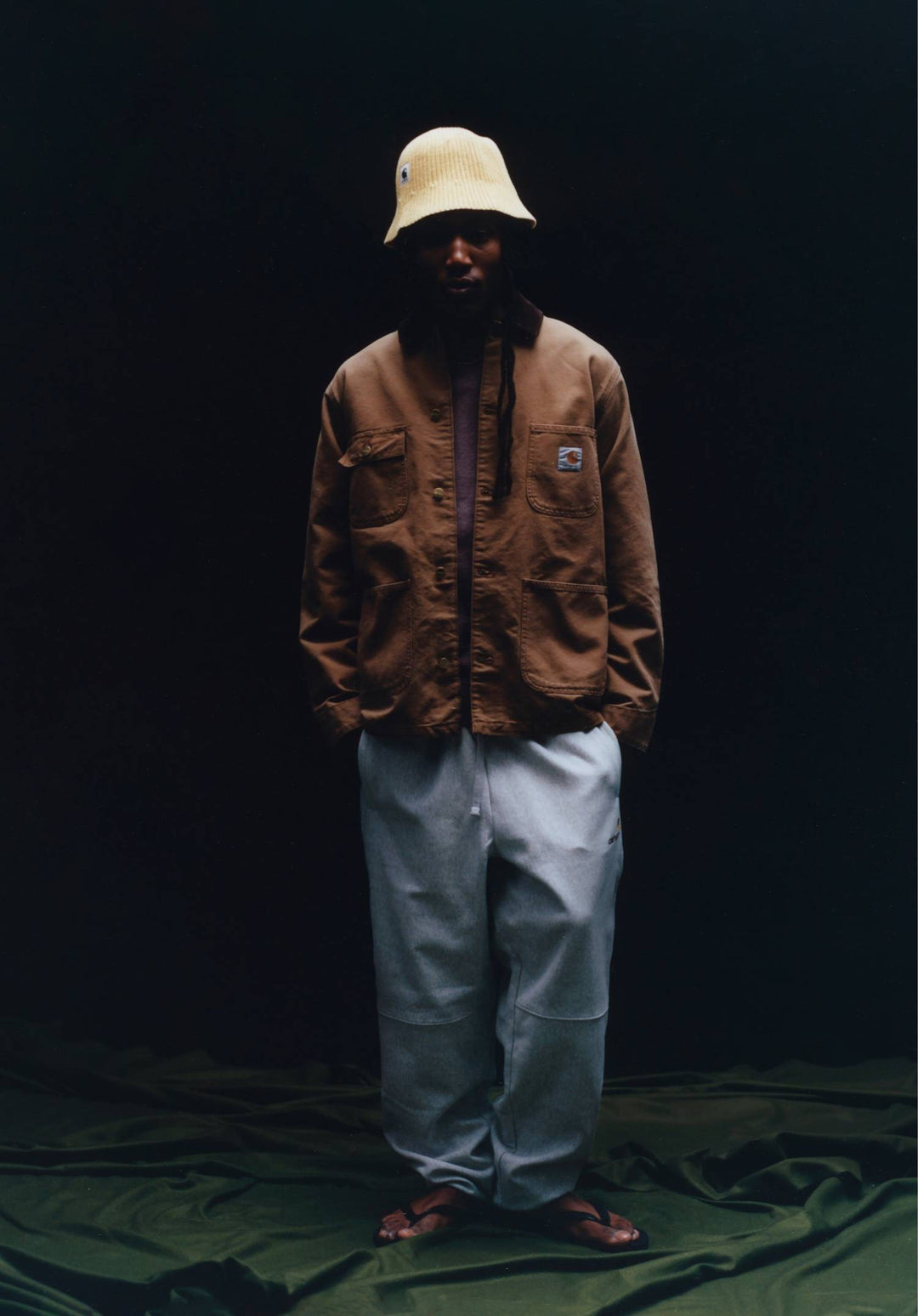

They’re a boxier shape too, why’s that?

Sunray is about the classic. Fashion changes, style doesn’t. We are not a fast fashion product, so it was paramount that our fit was a classic and not some scooped neck, twisty piece of jersey. The squarer, slightly boxier fit was designed for a reason. It was stylish without being fitted, the neck rib and shape was tighter than the modern lower versions being put out, the chest was loose to allow movement without being baggy and unkempt, the length has to be just below the stitch work on your jeans pocket to hide it but not too long so as not to be able to get your hands in easily, sleeve length had to be in proportion to the whole shape. We wanted you to notice that you did not notice you were wearing your T-shirt.

The feedback we have had from both customers and stores has been phenomenal. To be honest I am blown away by what we have heard, but again I must repeat that my guys in Japan have really helped pull this together in such an amazing way. A president of a very large US denim company contacted me to say that his Sunray T-shirt was the highest quality and best made tee he has ever owned. Phew, that is some praise. Given that very slow nature of the knit, the fact there is no tension and with no side seams means the T-shirts cannot go out of shape. We give all the jersey a pre-wash to help settle the layers, so even shrinkage is kept to almost zero. Modern volume made jersey is inherently unstable given how much tension is required to hold it all together, that when that is released, that instability comes even more apparent; hence the twisted seams after a wash, a shape that seems to not be the same as when you bought it etc.

I know we are a very young brand but to date we have not had one returned for being faulty. My quest for Japanese quality on antique machines is bearing fruit for everyone as we now all have less waste.

Tell us about the ‘Planet Friendly’ side of the brand…

Sunray had to be different in every way. The world does not need just another brand. It’s all about the tiny details. I wanted the very best quality, the very best fit, made with real thought and to be as planet friendly as possible. Most people who buy Sunray do not buy it because of our planet friendly initiatives. However, once they realise the effort that we have made to be planet friendly, that customer has an even bigger sense of satisfaction in the knowledge they have played their part. We have not really given these things much airtime, as for me it should be standard amongst all brands and not a Sunray soap box marketing exercise.

Through the effort we have put into our planet friendly initiatives, it would be great if the customer naturally becomes more self-aware that when buying their next item of clothing, they question; has that brand done their bit, can they do more, or is it all about bottom line? I want them to think, if a little brand in Cornwall can do it then why can’t’ they.

It is going to cost us all more money to help our planet, but we have NO choice and I am not ashamed to point out that our initiatives add around £3 to the end cost of our products. Isn’t that an investment worth making?

Without appearing to now be jumping on that soap box I am happy to highlight below the things that is incorporated into Sunray:

We use a very special Japanese cotton called Ochiwata that is recycled from the waste after the first comb. That combed and fluffy waste offers our jersey a real sumptuous and soft hand feel, giving every T-shirt a little uniqueness.

We use 100% compostable potato starch bags for the packaging. NO PLASTIC! We secure and personalise the packaging with a sticker that is fully recycled and fully compostable. Our hang tags are printed on recycled card using vegetable inks from a carbon neutral printer.

The wool that suspends the hang tags comes from an organic herd of rare breed of sheep that graze on Dartmoor. We have just signed up that every Sunray shipment will be climate neutral.

Lastly, and very important, you will notice there is no external branding. This statement is both design and planet friendly led. We produce classics. Producing something that is branded means it is probably fashion. Fashion dates; a classic doesn’t. When a classic is not being worn it is placed in your drawer and not landfill. Equally my quest to find that elusive high-quality unbranded T-shirt led me to work on Sunray, and if I was struggling, I was hoping there were others like me.

Having a bit of a rant, if everyone saw how complex and lengthy the process is to make cotton from little balls of fluff into stunning 1000’s of metres of yarn no one would ever buy a cheap T-shirt again, so how that store called No mark and others, you know the ones, can sell T-shirts for about £3 can only mean one thing, that people in the supply chain and the planet are being screwed. So is the end consumer, how many wears before that tee looks like a sack of s**t. That is waste, that is profit before thought.

There is currently a big thing about sustainability right now. It has become the new marketing cliché with most jumping on it for the next sale. It is wrong to make that your sole aim. If you design and produce something that does not fit, poor quality etc. then no amount of planet friendly bits will make it fit for purpose, so it quickly becomes waste and unnecessary. The primary focus must be that your design and quality allow your product to be desired, long lasting, fit for purpose and giving it reason to be there in the first place. Then it must be complete with as many planet friendly initiatives that you can find.

We feel we are thoughtful as opposed to sustainable.

What’s next for Sunray?

To slowly build a set of retailers who become great partners both domestically and internationally, which is already happening. The stores that we are now working with are real who’s who of premium menswear. Again, I need to mention I feel lucky to be working with these high street gems as without them Sunray is zilch.

I love walking into great stores that are beautifully curated, allowing your imagination to wander. They are under threat, which is why I have taken a very unmodern decision and one that every accountant will shake their heads in dismay at.

Sunray will never sell online itself and will never sell to pure on-liners.

These local museums of beautiful clothes have knowledge, great history and they bring a sense of community to their towns. They need supporting, hence our very unorthodox decision.